About Technology

Somac, the most powerful print security solution

- HOME

- About Technology

- Breathable Film Technology

Breathable Film Technology

Technology

Development of products tailored to the needs of customers

Breathable Film Technology

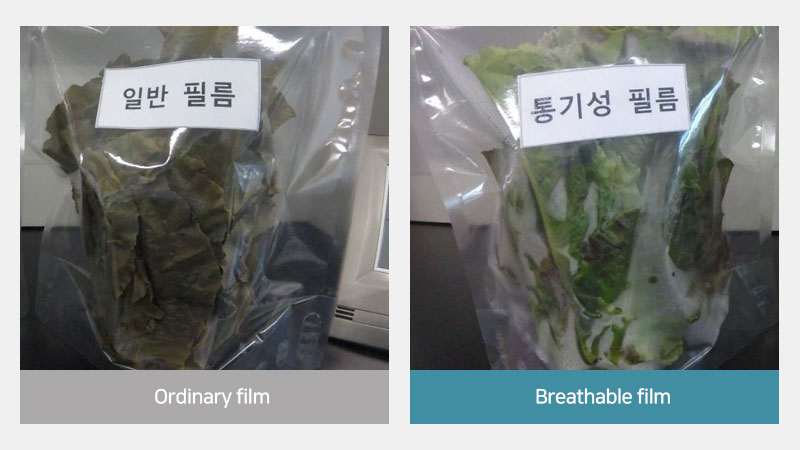

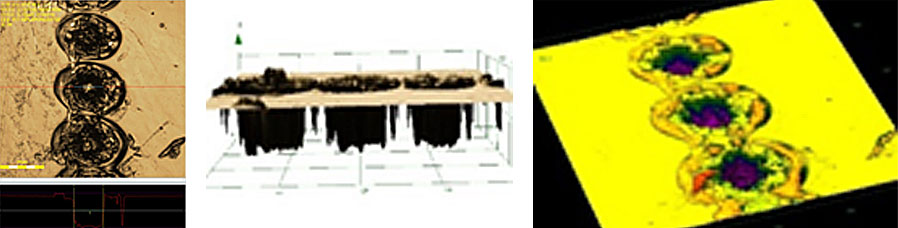

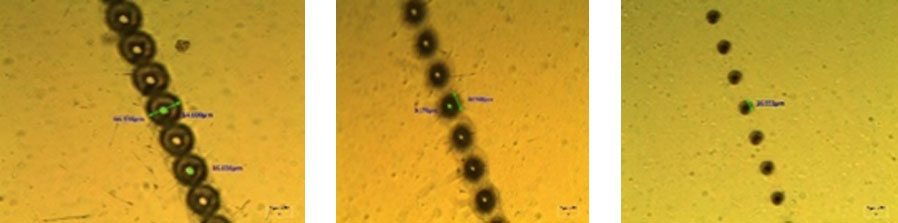

It is a type of air-permeable packaging material with pores formed on the cross-section or both sides of plastic film, The amount of gas permeation is artificially controlled to ensure that moisture is not released and only oxygen and gas are selectively permeated It is a special packaging material that improved storage heat and maintains functionality of package. According to customer’s request, it allows perforation/non-perforation adjustment to maintain oxygen permeability suited for product type and storage environment.

- Laser Ablation Technology

- Nano-second(10-9s) laser cutting is a method for eliminating the film surface by shock waves. As it is not a thermal energy processing method, no damage or structural change is caused around the processed surface.

- Digital precision control method

- It enables precise control of perforation/non-perforation, pore size, depth, number and clearance of pores.

Differentiation from competitors

왼쪽으로 드래그하시면 전체 표를 확인하실수 있습니다.

| Competitors | Conventional method | Processing method | 주요특징 |

|---|---|---|---|

| Competitor A | Mechanical Method (Perforated heat sink) |

Scratches on film, making the perforated |

|

| Competitor B | Chemical Method (Using chemicals) |

|

|

| Competitor C | CO2 Laser | CO2 Fine groove processing with the laser |

|

| Competitor D | Femtosecond, nanosecond (UV, IR) Laser |

|

|

| Somac | Nanosecond (UV, IR) Laser |

|

|

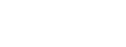

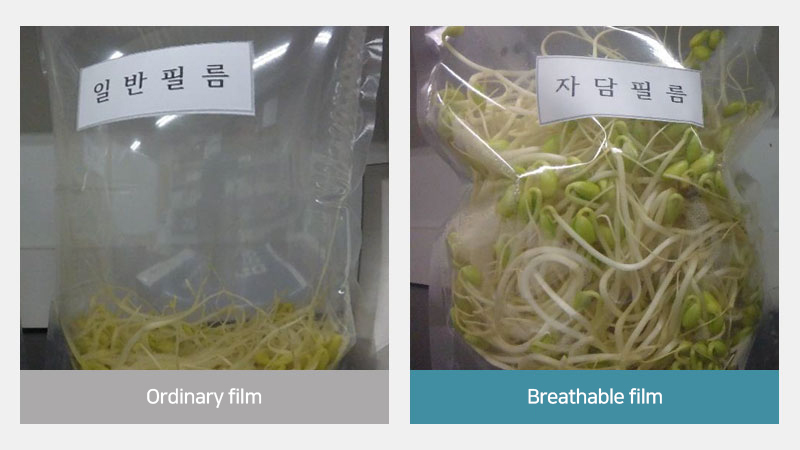

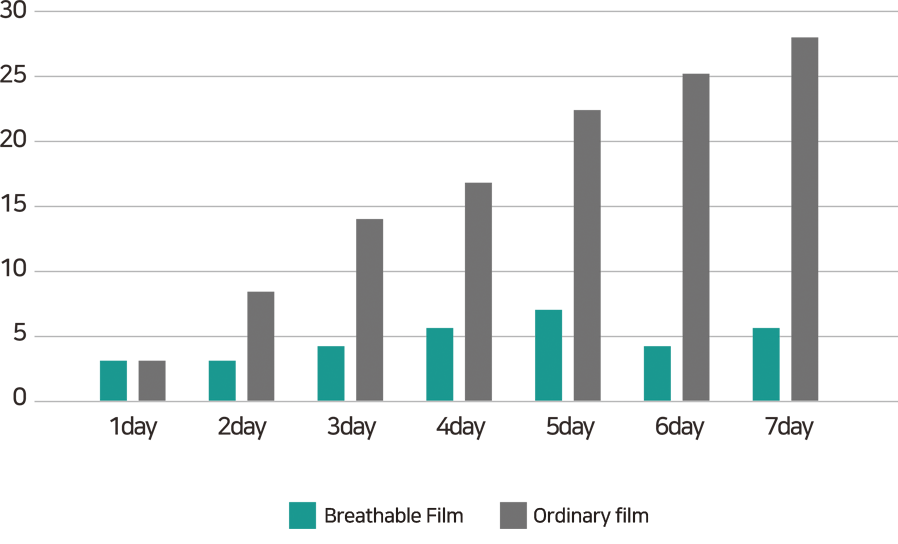

Storabilty test

Product: Bean Sprouts / Environmental Conditions: 25±5°C / 50±10%

CO₂Content in packaging materials

Breathable film: O2 CO2 are kept at constant level

O₂Content in packaging materials

Ordinary films: Increase in CO2and decrease in O2